This extreme heat dehydrates the material leaving a residue of fine white powder. The reduction unit of an aluminum plant consists of reduction pots or cells which are connected in series.

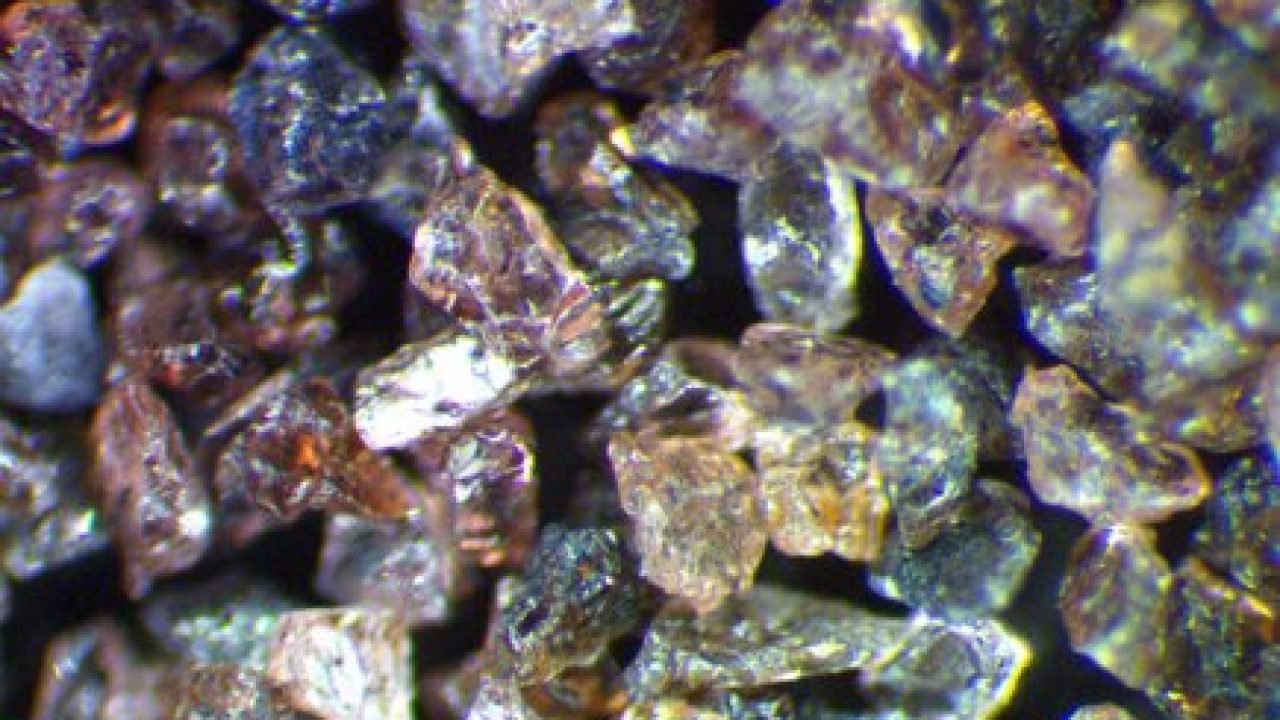

Sintered bauxite is often used as a sand-blasting abrasive.

Aluminum oxide powder uses. Aluminum oxide is a white odorless crystalline powder. Properties both physical and chemical vary according to the method of preparation. Anodic aluminum oxide AAO typically produced via the electrochemical oxidation of aluminum is a nanostructured aluminum-based material with a very unique structure.

AAO contains cylindrical pores that provide for a variety of uses. It is a thermally and mechanically stable compound while also being optically transparent and an electrical insulator. The pore size and thickness of AAO can.

Aluminium oxide is a chemical compound of aluminium and oxygen with the chemical formula Al 2 O 3It is the most commonly occurring of several aluminium oxides and specifically identified as aluminiumIII oxideIt is commonly called alumina and may also be called aloxide aloxite or alundum depending on particular forms or applications. It occurs naturally in its crystalline polymorphic. It is an aluminum oxide powder with a particle size distribution that centers around 3 microns.

It makes a great lapidary polish and produces a bright shine on almost any polish-worthy and well-prepared rock mineral or glass with a hardness between 5 and 8 on the Mohs hardness scale. We use TXP for its superior polishing abilities but we also use it because of its particle size. Aluminum Powder is used in the production of many types of explosives and fire works.

It is also employed in the manufacturing of certain types of electronics. Powdered aluminum is included in many paints and sealants. Certain products design to carry electrical current such as solar cells are often made using aluminum powder.

Rocket Fuel is often made with aluminum and many solid rocket. Aluminium hydroxide AlOH 3 is found in nature as the mineral gibbsite also known as hydrargillite and its three much rarer polymorphs. Bayerite doyleite and nordstranditeAluminium hydroxide is amphoteric ie it has both basic and acidic properties.

Closely related are aluminium oxide hydroxide AlOOH and aluminium oxide or alumina Al 2 O 3 the latter of which is also amphoteric. Aluminium oxide is a thermally unstable and insoluble compound that occurs naturally in various minerals such as corundum a crystalline variant of the oxide and bauxite which is considered as its principal aluminium ore 1. Here you will learn about.

What the main properties of aluminium oxide are. How aluminium oxide is produced. In this article after defining what sputtering is we aim to help you understand the sputtering process different types of sputtering methods with their advantages and limitations and applications of sputtering in various industries.

The final product from the Bayer process is alumina or aluminum oxide which has the appearance of a white powder. The reduction unit of an aluminum plant consists of reduction pots or cells which are connected in series. Each pot is made of a steel shell lined with carbon.

Molten cryolite a fluoride mineral containing aluminum oxide is poured into each pot and carbon. The first step in the process is to purify the bauxite into aluminum oxide which is a white powder from which aluminum can be extracted. The aluminum oxide must be made into the molten form so that electricity can pass through it in the next step of the process.

To achieve this it is dissolved into another compound that has a lower melting point. Once the aluminum compound is ready. Alumina Aluminum Oxide Al2O3 is an industrial ceramic that has high hardness is long wearing and can only be formed by diamond grinding.

Alumina ceramics are made from a white granular material or a very fine silky dense powder refined from bauxite. Alumina is a major engineering material that has excellent mechanical and electrical properties which makes it applicable for a wide range. Breakthrough speeds in aluminum part production have been achieved using the Aconity3D 1-kW MIDI system and Equispheres aluminum powder the two companies report.

Aconity3D is a manufacturer of custom and precise metal additive manufacturing AM printers and Equispheres produces specialized powders with unique attributes specifically designed for AM. Aluminium alloys are light strong and readily machined into shapes IPCS1997. See Sources of Human Exposure Anthropogenic Sources Uses for listings of industrial and non-industrial uses.

In spite of aluminium being highly electropositive ie readily forming positive ions it is resistant to corrosion because of the formation of a hard tough surface film of its oxide Cotton. Bauxite is a weathered rock containing two forms of hydrated aluminum oxide either mostly a monohydrate AlOOH in caustic bauxite or mostly a trihydrate AlOH 3 in lateric bauxite. Besides these compounds bauxite contains iron oxide which usually gives it a reddish-brown colour as well as silicates clay quartz and titanium oxide.

The crys-tal structure also contains 1220 by. This aluminum oxide dissolves in some chemicals notably strong acids and alkaline solutions. When the oxide film is removed the metal corrodes rapidly by uniform dissolution.

In general the oxide film is stable over a pH range of about 40 to 90 but there are exceptions. One of these exceptions is in environments where the surface film is insoluble but weak spots in the oxide film lead. Occurrence properties and uses.

Beryllium is a steel-gray metal that is quite brittle at room temperature and its chemical properties somewhat resemble those of aluminumIt does not occur free in nature. Beryllium is found in beryl and emerald minerals that were known to the ancient EgyptiansAlthough it had long been suspected that the two minerals were similar chemical confirmation of. Sodium hydroxide is used to manufacture many everyday products such as paper aluminum commercial drain and oven cleaners and soap and detergents.

Sodium Hydroxide in Cleaning Disinfectant Products. Sodium hydroxide is used to manufacture soaps and a variety of detergents used in homes and commercial applications. Chlorine bleach is produced by combining chlorine and.

This extreme heat dehydrates the material leaving a residue of fine white powder. Smelting 5 Smelting which separates the aluminum-oxygen compound alumina produced by the Bayer process is the next step in extracting pure metallic aluminum from bauxite. Although the procedure currently used derives from the electrolytic method invented contemporaneously by Charles Hall and.

There are anodized powder-coated electrophoresis coating and PVDF coating. With these properties the extruded aluminum tube has a wide range of applications in different area. Extruded Aluminum tubes also can be called aluminum pipes in material 6063 which are used in home fittings furniture and construction etc.

Wellste Aluminum tubing supply telescopic tube which can be used for a. Aluminum oxide sandpaper polishing powders and polishing suspensions are made from calcined alumina. Sintered bauxite is often used as a sand-blasting abrasive.

It is produced by crushing bauxite to a powder and then fusing it into spherical beads at a very high temperature. These beads are very hard and very durable. The beads are then sorted by size for use in different types of.

Powder coated aluminum windows have a top feature that makes the window clean durable weather-resistant and comes in a variety of colors. The most common is the RAL color which has about 200 standard colors. Beside powder coated finishing wellste has anodizing polishing brushed PVDF and electrophoresis coating as well.

SGS ISO Audited. Wellste a professional aluminum profiles for. Aluminum has a very high affinity to oxygen.

When a new aluminum surface is exposed in the presence of air or any other oxidizing agent it quickly develops a thin hard film of aluminum oxide or hydrated oxide in non-stagnant water. This aluminum oxidation is precisely what makes aluminum so corrosion-resistant. Talc mica octyldodecyl stearoyl stearate diisostearyl malate silica caprylyl glycol ethylhexylglycerin ptfe zinc stearate synthetic fluorphlogopite calcium titanium borosilicate calcium aluminum borosilicate calcium sodium borosilicate aluminum calcium sodium silicate alumina tin oxide ci 77891 titanium dioxide ci 77510 ferric ferrocyanide ci 77000 aluminum powder.

The microscopic grooves are then oxidized to form an oxide layer. Compared to normal aluminum products without finishes products made via this process are better in heat and corrosion resistance. Type 2 Anodizing Process.

Type 2 anodizing process uses sulfuric acid instead of chromic acid. Sulfuric acid is more potent leading to a better ejection of positive aluminum particles than what. The surface of the metal is converted to aluminum oxide as a.

White Aluminum Extrusion has a state-of-the-art vertical paint line powder coating system. WAE is your premier. WOOD GRAIN EFFECT - In its simplest aesthetic meaning wood grain is the alternating regions of relatively darker.

A thermal break is an element of low thermal conductivity.