Free silica crystalline silicon dioxide lead carbonate. Typical applications include the removal of rust.

Approximate cost per hour of blasting.

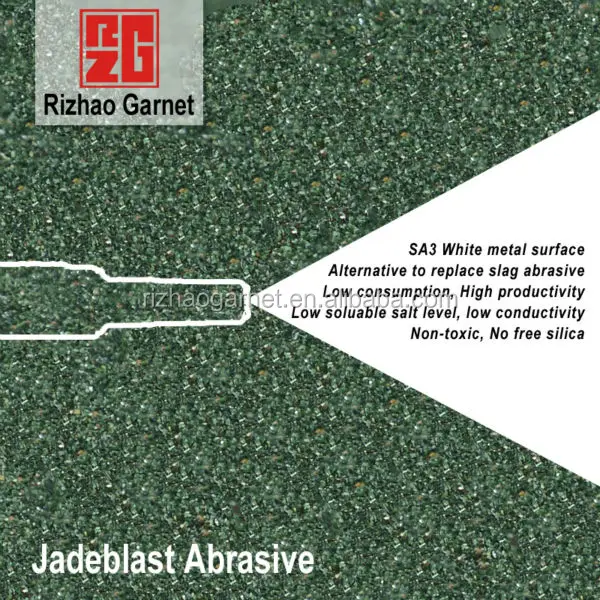

Abrasive free silica. Inhaling free silica particles is also associated with bronchitis and tuberculosis. Since 1974 the National Institute of Occupational Safety and Health NIOSH has recommended that silica sand or other substances containing more than 1 free silica be prohibited as an abrasive blasting material and that less hazardous substitutes be used. Abrasive blasting more commonly known as sandblasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface roughen a smooth surface shape a surface or remove surface contaminantsA pressurised fluid typically compressed air or a centrifugal wheel is used to propel the blasting material often called the media.

Using traditional sand is how abrasive blasting got coined as sandblasting media but its actually fallen out of favor in recent years due to one major reason. Sand includes silica which forms as dust when the sand erodes and poses a significant health hazard to those working with it. Silicosis is a deadly condition that affects people who breathe in these chemicals.

It is a relatively cheap low dusting abrasive with low free silica but is considered a dirty abrasive and not widely used in wet abrasive blasting because the high amount of fines fine particles mud up on the surface. Typical applications include the removal of rust. Sand Produces free silica.

Cause of silicosis a lung disease. Aluminum Oxide Lasts 30-40 X over sand. Silicon Carbide Lasts at least 40-50X over sand.

Sandblasting Process Pros Cons. The pros advantages of sandblasting are as follows. Abrasive action on the surfaceThe abrasive materials which are being used.

Harbor freight 20 lb sandblaster. Harbor freight 20 lb sandblaster. Approximate cost per hour of blasting.

Black Diamond Abrasive Blast Media 50-Lb. Whether your application is blasting vibratory parts drying refactory or lapping MFS carries a wide selection of abrasives for your industrial needs. The media is also durable re-usable and biodegradable and reduces cycle time of.

With a high-pressured system and the right abrasive this process can produce both a cleaning and finishing action for your surfaces. Its important to understand the different advantages and disadvantages of abrasive types. Check out our blast media chart to find the right one for the task at hand.

Media Type Description BestUse Grit Size Range Hardness Shape Surface Profile Speed. In addition to this glass bead blasting media contains no lead 2 or free silica making it safe for the environment and the person doing the cleaning. Aluminum Oxide Blast Media.

Aluminum Oxide is one of the most commonly used abrasives in blast cleaning that costs around 2 to 250 per pound. Its found in many cleaning products due to its hardness and strength but its mostly used. In 1974 NIOSH recommended that silica sand or other substances containing more than 1 free silica be prohibited as abrasive blasting material and that less hazardous materials be used in blasting operations NIOSH 1974b.

The current OSHA permissible exposure limit PEL for respirable crystalline silica quartz is 100 µgm 3 as an 8-hour time-weighted average. The specific gravity of alumina is just over half that of chilled iron so that this type of abrasive is readily picked up by the suction feed and is effectively accelerated through the blasting nozzle. The rate of breakdown is not excessive when used at moderate air pressures.

Brown fused alumina is the more commonly used grit medium and is extremely hard 9 on the Mohs scale. Consider Silica Packs to Keep Jewelry Moisture-Free. Silica packs are often found inside new shoes shoe boxes and sometimes in clothing.

They are used to keep these products moisture-free. The next time you find one keep it and store it with your silver to prevent it from tarnishing. You can also purchase silica packs.

Try Anti-Tarnish Cloths for a Quick Clean. Molding American English or moulding British and Commonwealth English. See spelling differences is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix.

This itself may have been made using a pattern or model of the final object. A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as. Compression of oxygen and hydrogen.

Oil extraction Manufacture of manganese and its compounds. Flammable liquids and compressed gases. Non Mandatory Standards on OSH for.

Free silica crystalline silicon dioxide lead carbonate. Methanol methyl alcohol if the substance contains more than 1 per cent by volume. Tetrachloromethane carbon tetrachloride tributyl tin.

Register of hazardous chemicals. Before you start your register of hazardous chemicals you must have an up-to-date compliant safety data sheet SDS for each chemical. CLEANING ABRASIVE BLACK DIAMOND pn 78B Price.

Qty Black Diamond media cleans faster and produces less dust than any other media. Environmentally safer than Silica Sand as it contains no health threatening Free Silica dust. Perfect for Sandblasters and Spark Plug Cleaners.

CLEANING ABRASIVE BLACK DIAMOND pn 78B Price. Qty Black Diamond media cleans faster and produces less dust than any other media. Environmentally safer than Silica Sand as it contains no health threatening Free Silica dust.

Perfect for Sandblasters and Spark Plug Cleaners. Starblast is a high-efficiency low-dusting low-free-silica blasting abrasive that removes rust mill scale and weathered coatings from bridges and other structures. The companys portfolio also includes five grades of zircon used in precision investment casting foundry refractory ceramic and other segments.

Propellants Chemours employs safety science and technology to create. Sand or other substance containing free silica. Use as an abrasive for blasting articles in any blasting apparatus.

A substance a containing compounds of silicon calculated as silica to the extent of more than 3 per cent by weight of dry material other than natural sand zirconium silicate zircon calcined china clay calcined aluminous fireclay sillimanite calcined or fused. Coating processes are commonly used in materials science to protect a core or modify material properties. We describe a hydrothermal coating process using TEOS tetraethyl orthosilicate a widely used precursor for silica coatings on three representative template materials carbon nanotubes silica and polystyrene nanoparticles with different properties and shapes.

17 Turning or dressing of an abrasive wheel. 18 The handling in open vessels or manipulation of strong acid or dangerous corrosive liquids or materials and the operation maintenance or dismantling of plant or any part of plant being plant or part of plant which contains or has contained such acids liquids or materials unless the plants or part of the plant has been so prepared by. The Code of Federal Regulations CFR is the official legal print publication containing the codification of the general and permanent rules published in the Federal Register by the departments and agencies of the Federal Government.

The Electronic Code of Federal Regulations eCFR is a continuously updated online version of the CFR. It is not an official legal edition of the CFR. Aluminium hydroxide is used widely in non-prescription stomach antacids in buffered analgesics and other pharmaceuticals and in antiperspirants and dentifrices as a filler in cosmetics plastics rubber and paper and as a soft abrasive for brass and plastics ATSDR 1999.

It is also used pharmaceutically to lower the plasma phosphorus levels in patients with renal failure. Watch for FREE over 100000 Indian xxx videos. All Indian Sex Videos can be downloaded 100 free at Hindipornvideosinfo.